Product Description

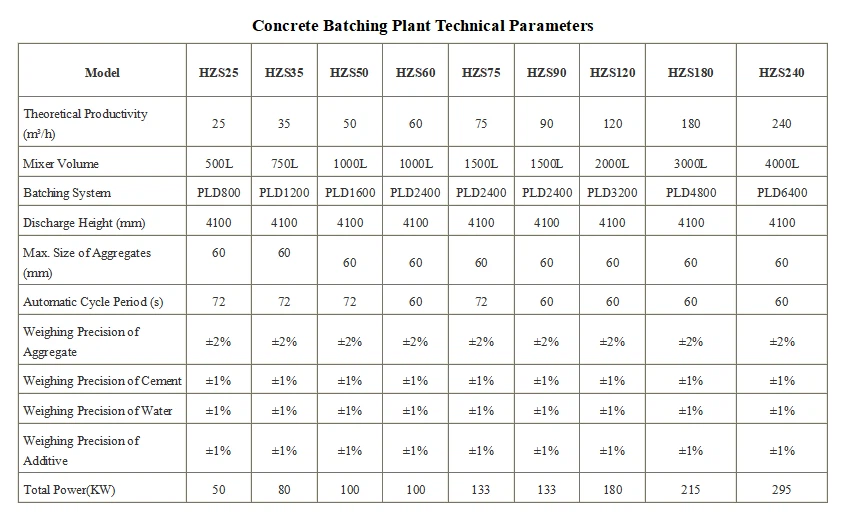

A modular concrete plant is a concrete batching plant designed with pre-assembled, transportable components, allowing for quick on-site assembly. It produces concrete by mixing cement, water, aggregates, and additives. They cater to various construction needs, such as infrastructure projects, commercial buildings, residential structures, precast concrete production, and large-scale industrial developments. Their precise batching, mixing, and discharging processes, typically managed by automated systems, ensure consistent quality in every batch.

Product Advantages

Quick Installation

The pre-assembled components of modular concrete plants allow for rapid on-site assembly, reducing downtime and accelerating project timelines. These includes pre-wired electrical systems, pre-plumbed water lines, and pre-installed mixers that simply need to be connected on-site, significantly reducing assembly time. As a result, these plants can be installed and made operational in 2-3 days, compared to traditional plants that may take 1-2 weeks due to more complex assembly work. This quick assembly is especially valuable for urgent projects like road repairs after a severe storm, or constructing temporary bridges after a natural disaster to restore access in affected areas.

Flexibility

The modular design allows for adding or removing modules as needed, adapting to a wide range of construction requirements. For instance, a modular plant used for a high-rise residential project can be quickly reconfigured to produce specialized mixes like self-compacting concrete by adding a module for chemical admixtures that enhance flowability. Moreover, the same plant can adjust to produce concrete for different projects by modifying the batching settings. For example, it could switch from a high-strength mix to a standard 30 MPa concrete suitable for foundations by adjusting the cement ratio and aggregate type through the plant's automated control system.

Cost-Effective

A modular plant's setup cost is 20-30% lower than that of a traditional concrete batching plant due to its simpler foundation requirements and shorter installation time. The simpler foundation requirements stem from the plant's lighter weight and pre-assembled modules, which are usually placed on a concrete slab which simpler and quicker to construct. While traditional plants require reinforced concrete structures to support the weight of a larger, heavier plant. Shorter installation time is achieved because the pre-wired and pre-assembled modules can be connected on-site in 2-3 days, while traditional plants require more time-consuming assembly and testing. This streamlined process can save up to $50,000-$100,000 in setup costs for medium-sized projects like constructing a 10-story residential building.

Ease of Maintenance

The modular design of these plants makes maintenance easier because each part can be easily accessed. For example, if a mixing drum requires replacement, the specific module housing it can be swapped out compared to traditional plants where repairs could take 1-2 days because traditional plants often have integrated components, making it necessary to dismantle multiple parts to access the area needing repair.

Improved Quality Control

Automated systems in modular plants can precisely control the amount of the mixture. For example, the automated batching systems can maintain a water-cement ratio with a precision of ±1%, which means that if the desired ratio is 0.45, the system will keep it between 0.445 and 0.455. This level of accuracy ensures that each batch of concrete achieves the intended strength and density, which is especially important for bridge construction where any variation could impact load-bearing capacity.

Hot Tags: modular concrete plant, China modular concrete plant manufacturers, suppliers, factory, smart concrete mixer, modular concrete plant, skip concrete batching plant, brick mixer, precast concrete mixer, wet mix concrete batching plant